Our services

Empowering Automation Excellence with NexaNeon

Implementation of Automation and Industrial IT Solutions

At NexaNeon, we specialize in the tailored implementation of cutting-edge Automation and Industrial IT Solutions that transform operational dynamics and drive efficiencies. Our approach begins with a deep understanding of your specific industrial challenges, enabling us to design and deploy integrated systems that streamline processes and enhance productivity. From the initial concept to final execution, our expert team ensures seamless integration of advanced automation technologies and robust IT infrastructures, delivering solutions that are not only reliable but also scalable. Whether automating discrete manufacturing processes or implementing comprehensive industrial networks, NexaNeon is dedicated to equipping your business with the tools it needs to thrive in an increasingly digital landscape, ensuring that every solution is a step towards enhancing your operational excellence.

Industrial Production Line Supervision

At NexaNeon, our Industrial Production Line Supervision service ensures that your manufacturing operations are optimized for maximum efficiency and product quality. Leveraging advanced monitoring technologies and real-time data analytics, we oversee every aspect of the production process, from raw material handling to final product assembly. Our team of experts implements sophisticated control systems to detect and address deviations, minimize downtime, and maintain consistent output standards. With NexaNeon’s supervision, you can trust that your production line is not only meeting but exceeding industry standards, providing you with a competitive edge in today’s fast-paced market.

PLC System Integration and Setup

NexaNeon excels in Programmable Logic Controller (PLC) System Integration and Setup, providing bespoke solutions that streamline and enhance industrial automation processes. Our service encompasses the full lifecycle of PLC implementation—from initial system design and configuration to integration and ongoing support. We work closely with our clients to understand their specific operational needs, enabling us to tailor PLC systems that optimize production efficiency, reliability, and scalability. Our team of automation experts ensures seamless integration with existing machinery and networks, employing cutting-edge technology to deliver robust and flexible control systems. With NexaNeon, elevate your facility’s automation capabilities with PLC systems that bring precision, adaptability, and enhanced control to your operations.

Values

Maximize Uptime and Extend Equipment Life with NexaNeon Maintenance Services

Enhanced Production Efficiency

Automating your production lines with our sophisticated systems ensures operations are streamlined and efficient. This leads to faster production times and a higher quality of output, enhancing overall operational efficiency.

Advanced System Integration

Our expertise in integrating complex automation solutions allows for seamless communication between different technologies and machinery, improving system reliability and functionality.

Reduced Operational Risks

Implementing our cutting-edge monitoring and control systems significantly reduces operational risks, ensuring machinery operates within safe parameters and minimizes the chance of costly downtimes.

Customized Automation Solutions

We customize our automation services to fit the specific needs of your operations, ensuring that every solution maximizes productivity and efficiency tailored to your unique requirements.

Sustainable Operations

Our automation solutions are designed not only for efficiency but also sustainability. We help reduce energy consumption and waste, contributing to more environmentally friendly operations.

Maintenance Solutions

Ensuring Operational Excellence with NexaNeon's Comprehensive Maintenance Services

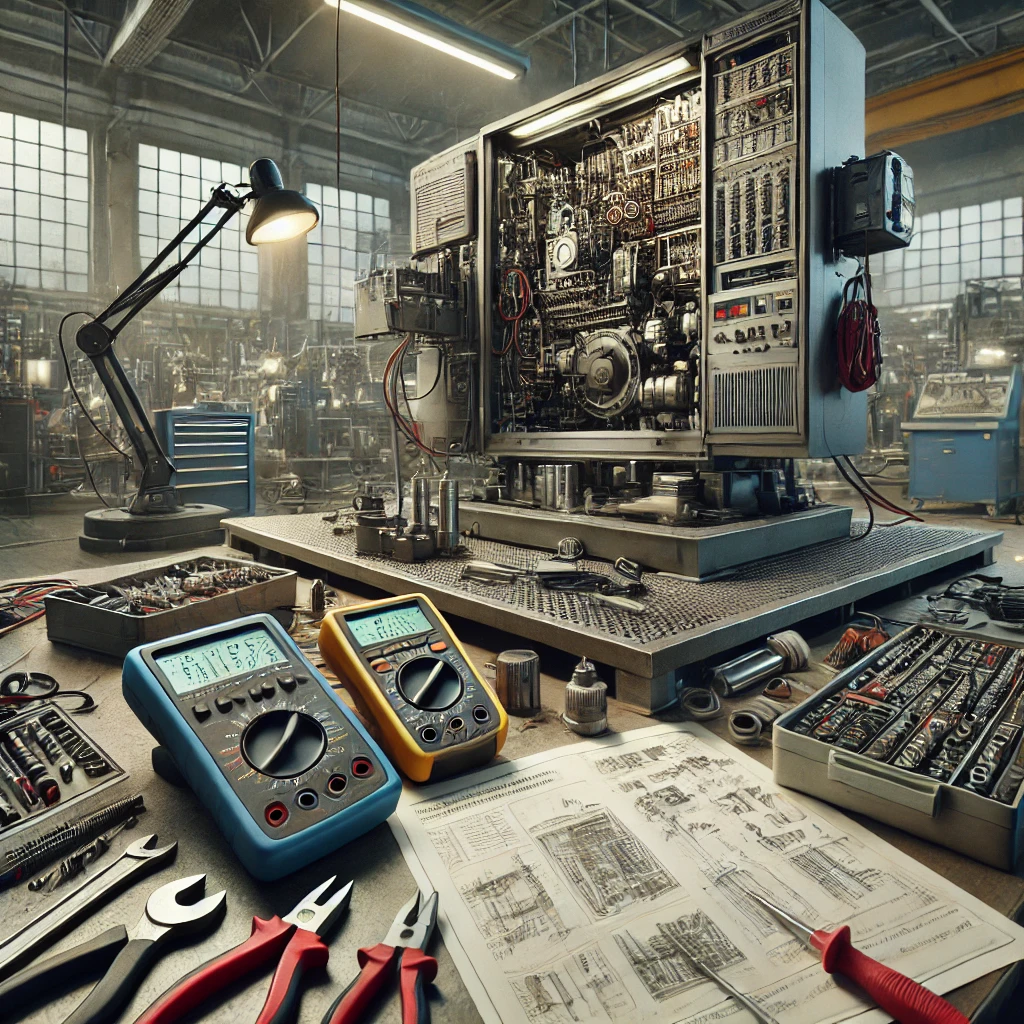

Curative Maintenance

also known as corrective maintenance, is performed after a failure has occurred, with the aim to restore the equipment to its proper working condition. Here’s our process for handling corrective maintenance::

We understand that downtime is costly. Our maintenance teams are ready to respond quickly to repair calls to minimize disruption to your operations.

Using advanced diagnostic tools and techniques, we identify the root cause of the failure. This step is crucial to ensuring the correct repairs are made and similar issues are prevented in the future.

Our skilled technicians carry out repairs using high-quality parts and materials. We strive not only to fix the immediate problem but also to ensure that repairs contribute to the long-term reliability of the equipment.

After repairs, we thoroughly test the equipment to confirm it is operating correctly and safely before it is put back into service.

We review each incident of corrective maintenance to learn from failures and refine our preventive maintenance strategies accordingly.

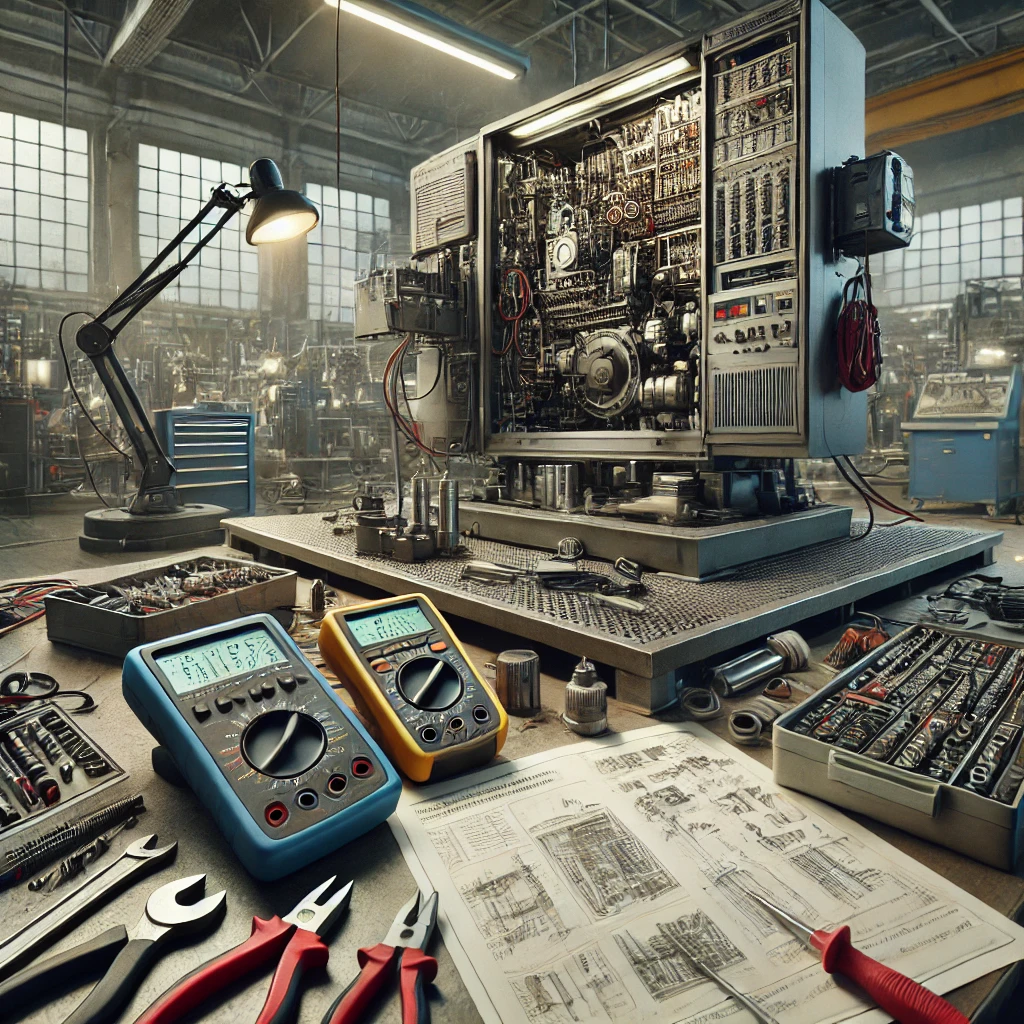

Preventive Maintenance

involves a systematic approach to maintaining equipment before problems occur. This proactive service is designed to keep your machinery running smoothly and prevent the unexpected breakdowns that can disrupt operations and lead to costly downtime. Here’s how we implement preventive maintenance:

We conduct thorough inspections of machinery to identify any signs of wear and tear or potential issues. This includes checking for leaks, wear in moving parts, and testing electrical systems and controls.

Our routine maintenance tasks may include lubrication, cleaning, adjustments, and replacing parts that are known to wear down over time, such as filters and belts. These tasks are scheduled based on the manufacturer’s recommendations and our own experience with similar equipment.

We plan and schedule service visits that are convenient for you, ensuring minimal disruption to your operations. These services are conducted at intervals that align with your equipment’s usage patterns and operational demands.

After each maintenance session, we provide a detailed report outlining what was done, any issues found, and recommendations for future maintenance or repairs. This helps in maintaining a clear maintenance log and planning future interventions.

Equipment List

Explore the Wide Range of Industrial Equipment Expertly Maintained by NexaNeon

Trusted Brands We Service

Our clients