Our services

NexaNeon's Expertise in Industrial Electronic Equipment Maintenance

Preventive Maintenance Services

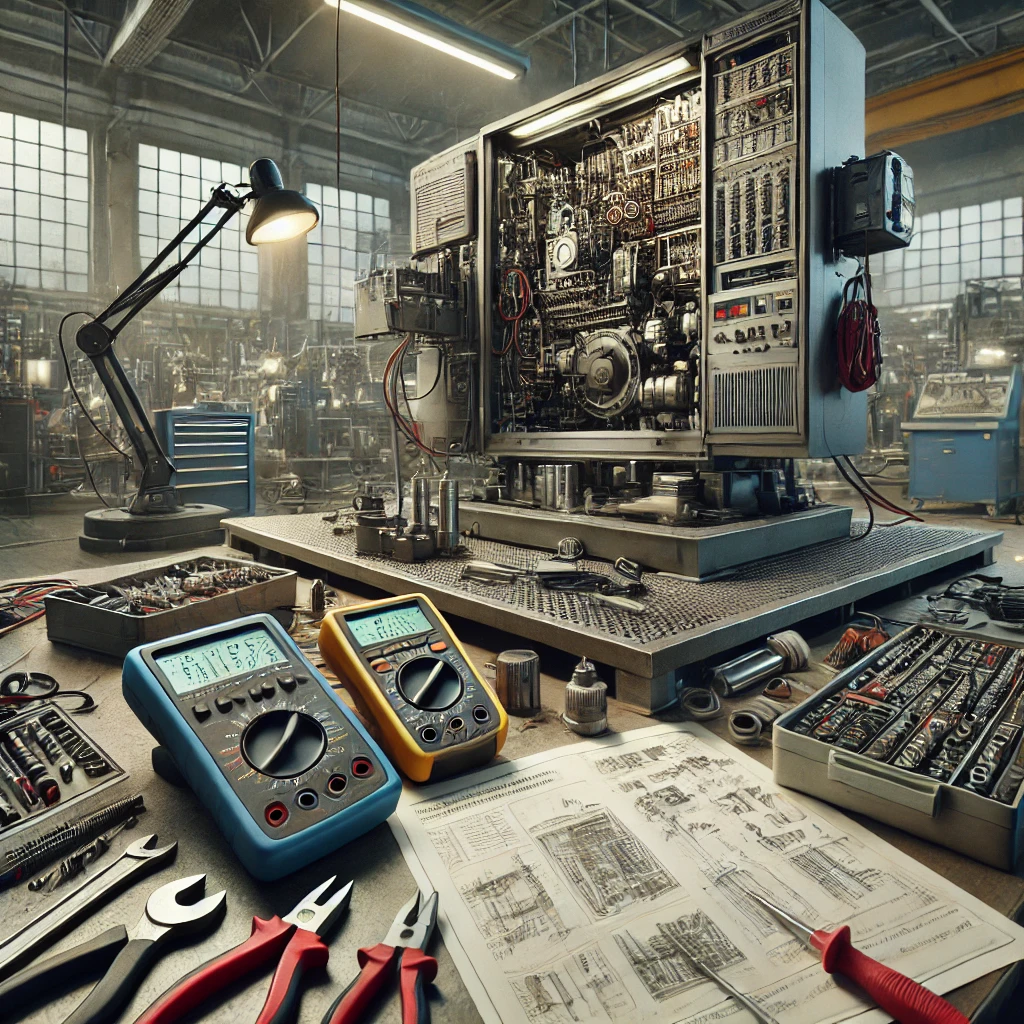

At NexaNeon, our Preventive Maintenance Services are designed to keep your industrial equipment running at peak efficiency. We focus on early detection and correction of potential issues before they evolve into costly repairs, ensuring minimal downtime and maximum productivity. Our team of skilled technicians employs the latest diagnostic tools and techniques to systematically inspect, clean, and repair your machinery. Trust us to extend the lifespan of your equipment and optimize its performance through strategic, scheduled interventions tailored to your operational needs.

Curative Maintenance Services

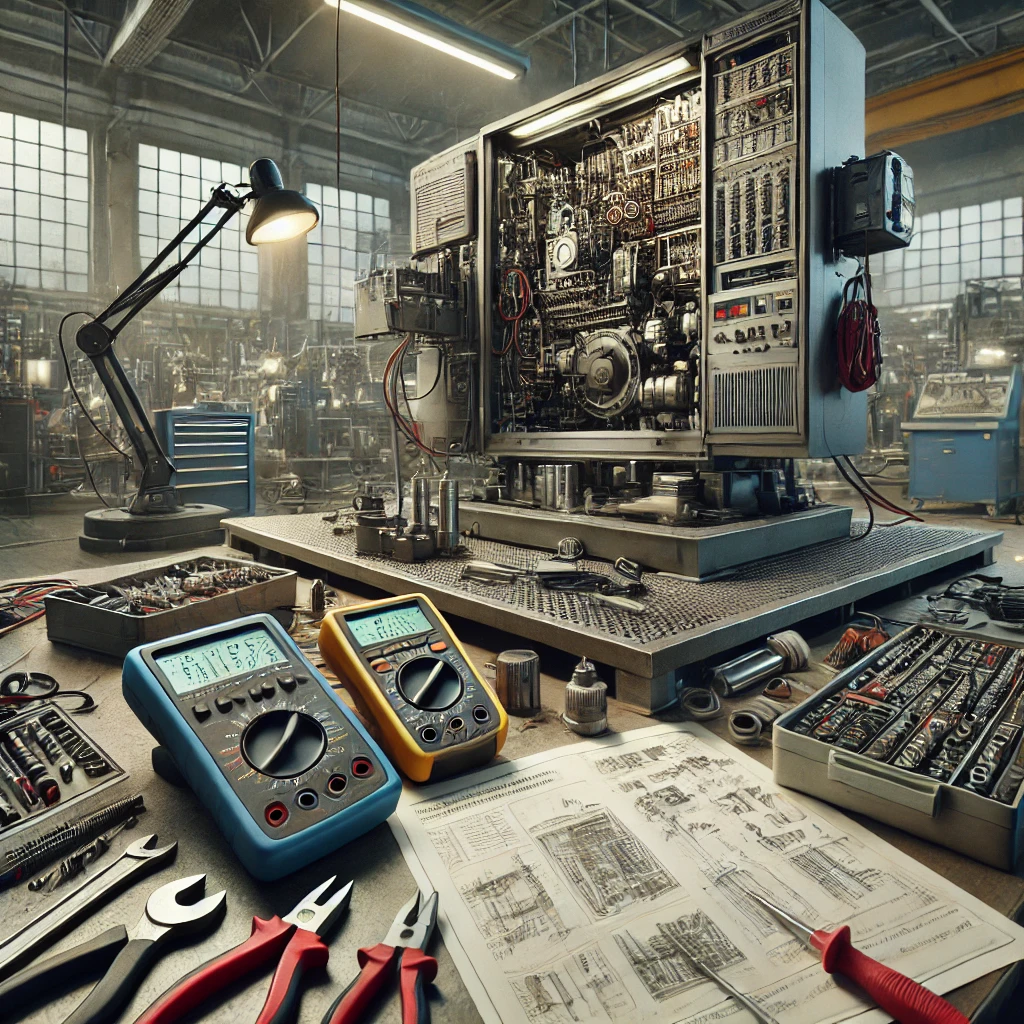

NexaNeon’s Curative Maintenance Services provide swift and effective solutions to restore your industrial equipment to optimal working condition. Specializing in reactive maintenance, our experienced technicians address breakdowns and malfunctions with precision and urgency. We diagnose issues thoroughly and perform necessary repairs using high-quality parts and advanced techniques. Our goal is to minimize downtime and ensure your machinery is back in operation as quickly as possible, with lasting repairs that prevent future disruptions. Trust our expertise to maintain the continuity and efficiency of your production processes.

Project Management and Consultation Services

Benefit from our end-to-end project management services, guiding your projects from inception through completion. We provide expert consultation to optimize your systems and processes, ensuring timely delivery within budget.

Values

Maximize Uptime and Extend Equipment Life with NexaNeon Maintenance Services

Prevent Premature Equipment Failure

Regular maintenance checks and proactive servicing prevent the early wear and tear of critical components, significantly extending the operational life of your machinery.

Optimize Performance

Our maintenance routines fine-tune your equipment, ensuring it runs at peak efficiency. This optimization not only boosts productivity but also conserves energy, contributing to a more sustainable operation.

Reduce Downtime and Operational Costs

By identifying and addressing potential issues before they turn into costly repairs or cause operational disruptions, our services keep your machinery in continuous, efficient operation. This approach minimizes downtime, reduces repair costs, and maintains consistent production levels, ensuring your operations stay cost-effective.

Compliance and Safety

Our services ensure that your equipment remains compliant with the latest safety standards and regulations, reducing the risk of accidents and legal liabilities.

Customized Service Plans

We tailor our maintenance services to meet the specific needs of your operations, ensuring that each piece of equipment receives attention based on its usage and operational demands, which further enhances efficiency and extends lifespan.

Maintenance Solutions

Ensuring Operational Excellence with NexaNeon's Comprehensive Maintenance Services

Curative Maintenance

also known as corrective maintenance, is performed after a failure has occurred, with the aim to restore the equipment to its proper working condition. Here’s our process for handling corrective maintenance::

We understand that downtime is costly. Our maintenance teams are ready to respond quickly to repair calls to minimize disruption to your operations.

Using advanced diagnostic tools and techniques, we identify the root cause of the failure. This step is crucial to ensuring the correct repairs are made and similar issues are prevented in the future.

Our skilled technicians carry out repairs using high-quality parts and materials. We strive not only to fix the immediate problem but also to ensure that repairs contribute to the long-term reliability of the equipment.

After repairs, we thoroughly test the equipment to confirm it is operating correctly and safely before it is put back into service.

We review each incident of corrective maintenance to learn from failures and refine our preventive maintenance strategies accordingly.

Preventive Maintenance

involves a systematic approach to maintaining equipment before problems occur. This proactive service is designed to keep your machinery running smoothly and prevent the unexpected breakdowns that can disrupt operations and lead to costly downtime. Here’s how we implement preventive maintenance:

We conduct thorough inspections of machinery to identify any signs of wear and tear or potential issues. This includes checking for leaks, wear in moving parts, and testing electrical systems and controls.

Our routine maintenance tasks may include lubrication, cleaning, adjustments, and replacing parts that are known to wear down over time, such as filters and belts. These tasks are scheduled based on the manufacturer’s recommendations and our own experience with similar equipment.

We plan and schedule service visits that are convenient for you, ensuring minimal disruption to your operations. These services are conducted at intervals that align with your equipment’s usage patterns and operational demands.

After each maintenance session, we provide a detailed report outlining what was done, any issues found, and recommendations for future maintenance or repairs. This helps in maintaining a clear maintenance log and planning future interventions.

Equipment List

Explore the Wide Range of Industrial Equipment Expertly Maintained by NexaNeon

Trusted Brands We Service

Our clients